Veegeo is a team of geothermal specialists

Driven and sustainable: from realisation to management of the geothermal operation.

Production and Reservoir Engineering

Production monitoring and optimisation || Well testing || Completion and ESP design || Well integrity monitoring || Scaling and corrosion management || Well stimulation || Reservoir engineering and History matching

Geothermal Project Management

Budget, planning, and quality assurance || Coordination design team geothermal system || Coordination contractors || Well intervention and workover management

Consultancy and Due Diligence

Decision processes during design and project realisation || Set up and execute R&D projects || Oil and gas synergies || Due diligence

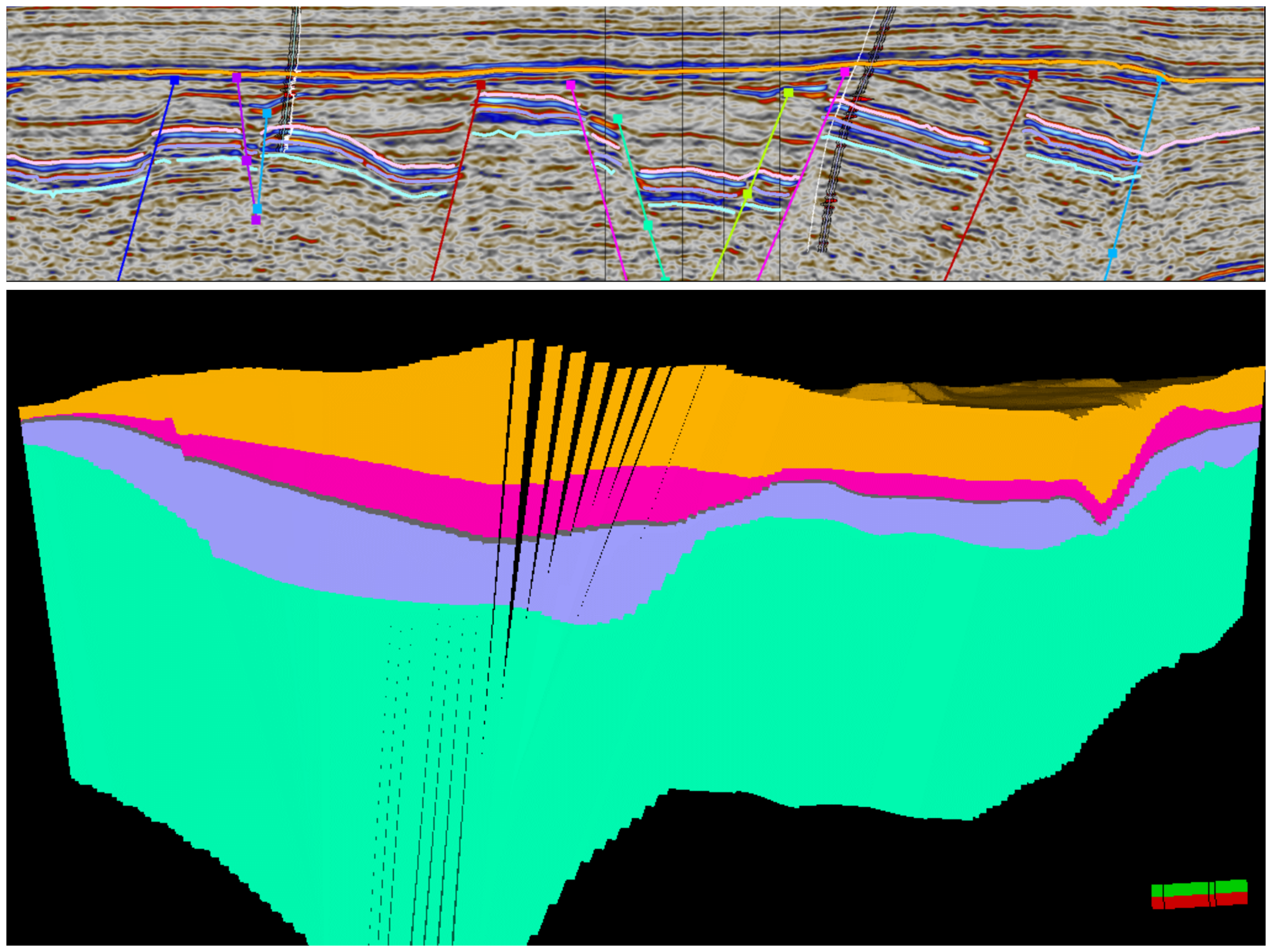

Geological Evaluations and Geo-hazard Management

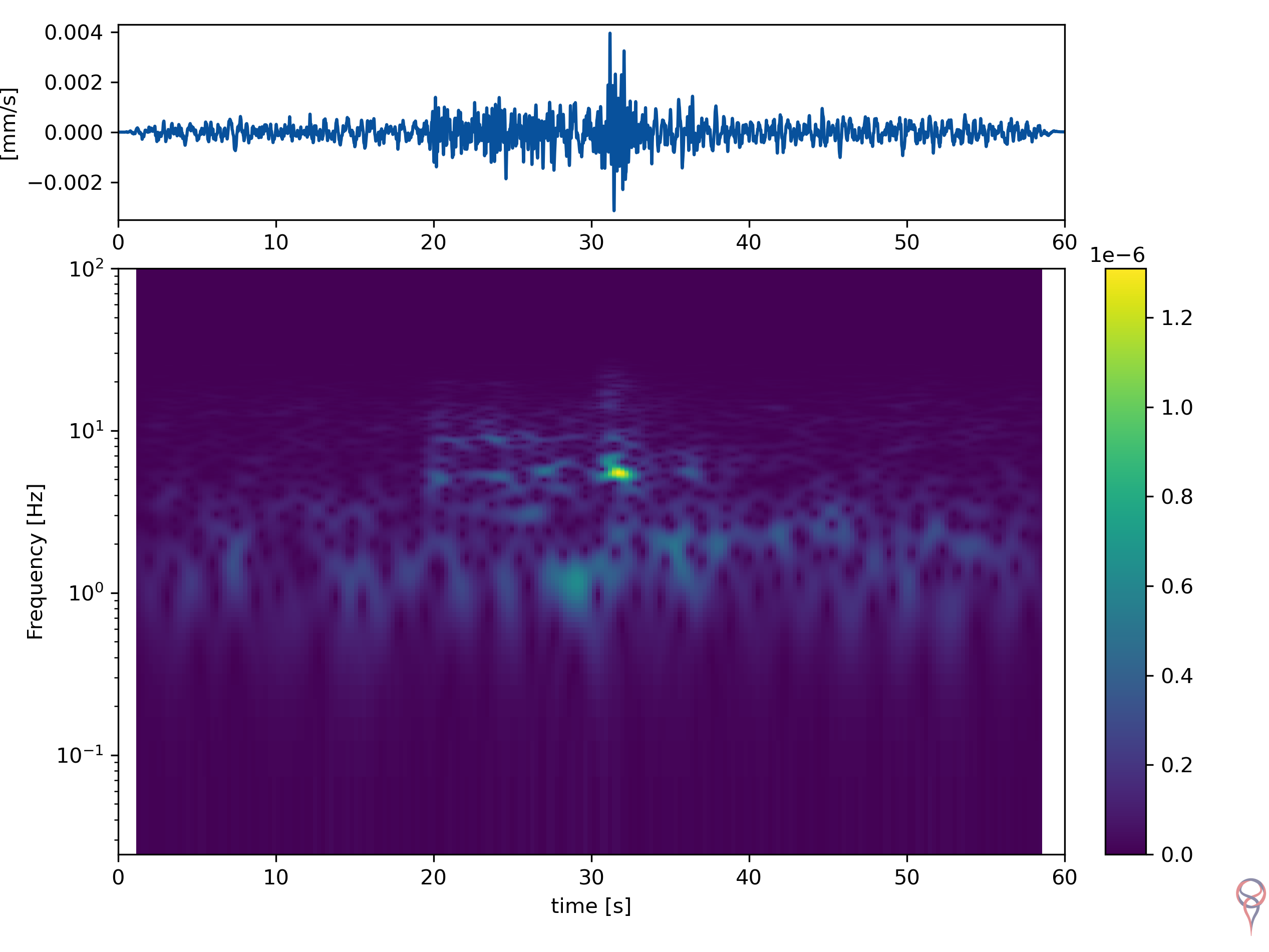

Geological evaluations || Static and dynamic modelling || Seismic Hazard and Risk Analyses (SHRA) || Monitoring and analysing seismic activity (incl. baseline) near geothermal operation || Seismic Risk Management Plan || Subsidence monitoring (based on InSar) || Subsidence Risk Management Plan

Projects that we're proud of:

Geothermal production support to eight doublets

Throughout the year Veegeo is responsible for geothermal production support for eight doublets: Tria ...

Design and installation GRE-lined wells

Veegeo designed a corrosion barrier for the first Trias Westland doublet. This barrier consists of a ...

Geological Subsurface Model and Advice Geo-hazards

Veegeo supports Ennatuurlijk with geological evaluations for the development of their geothermal ope ...

Seismic monitoring at nine geothermal operations

Veegeo provides seismic monitoring at nine geothermal operations (15 producing doublets, and 1 minew ...